Quality since 1954

Drawing on our many years of experience and with the assistance of our trained specialists and engineers, Rudischhauser Surgical Instruments Manufacturing GmbH has been developing and manufacturing medical products of the highest quality since 1954 using the latest development and production technology.

Aided by our own design and development department, we develop the perfect customised solution for each individual product in close cooperation with customers located all over the world. We meet the current statutory requirements relevant to each specific case through standardised and validated processes and procedures for their products, thus ensuring their competitiveness on the international market.

Special surface coatings, UDI-compliant laser marking and labeling according to customer specifications round off your product.

The company is certified pursuant to DIN EN ISO 13485:2016 and registered with the FDA (Food and Drug Administration) in the United States pursuant to the FDA 21 CFR, Part 820 standard with Registration No. 8010300.

Foundation

Relocation to larger premises

Expansion of the production facility

New management

Change in management

New building and relocation

DIN EN 13485 certification also for implants

Automation of the milling department

New cleaning system

New COO

Expansion of the office space

Introduction of CAQ system

At a glance

Employees

52 employees

Experience

Over 70 years of experience

in the production

of medical instruments

Customers

160 customers

Worldwide

Investments

Over € 7.4 M

invested over the

last 10 years

Production area

Production area

1700 m² (18,298.6 ft²)

Products

Own product line

of instruments and sets

Technical R&D

Support

CAD/CAM department

(SOLIDWORKS & SolidCAM)

Certified

DIN EN 13485:2021 certified for the production of surgical instruments and implants

FDA approved

Instruments &

Implants

45% spine

25% orthopaedics

25% traumatology

5% miscellaneous

Facts and figures

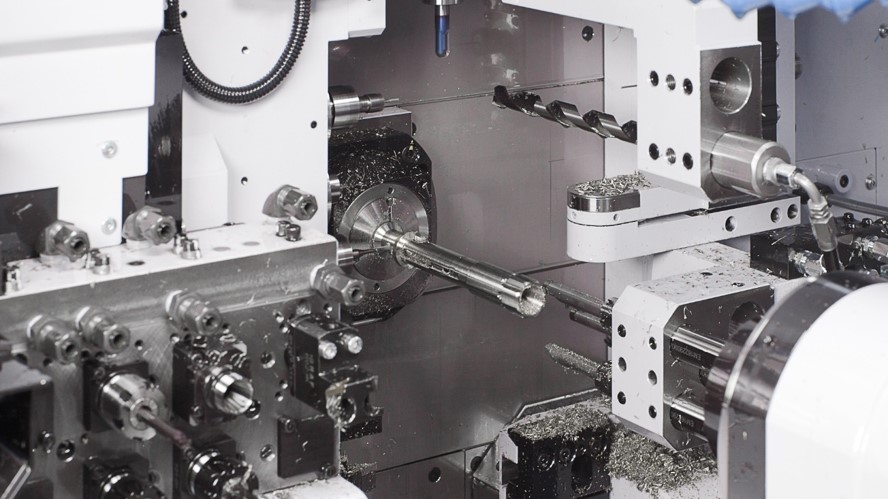

- CNC sliding headstock automatic lathes: 9 machines

- CNC machining centers: 6 machines

- Quality control: 4 employees

- Technical support: 4 employees

- Glass bead & grit blasting: 4 shot-blast machines

- Laser marking | UDI: 2 laser marking systems

- Laser welding: 2 laser welding systems

- Polishing: Manual | Electrolytic

- Coating | Surface treatment: DLC | AlTiN | Titanium anodizing

- Final cleaning | Labeling | Packaging

Manufacturing Capabilities

Complete listing

Machine | Type |

|---|---|

STAR SV-20R | CNC sliding headstock automatic lathe |

STAR SR-20J | CNC sliding headstock automatic lathe |

STAR SR-20RII | CNC sliding headstock automatic lathe |

STAR SV-32 | CNC sliding headstock automatic lathe |

STAR SR-38-B | CNC sliding headstock automatic lathe |

Hanwha XD20V | CNC sliding headstock automatic lathe |

Hanwha XD20V | CNC sliding headstock automatic lathe |

Hanwha XD38II | CNC sliding headstock automatic lathe |

Hanwha XD12II | CNC sliding headstock automatic lathe |

Machine | Type | Robot system |

|---|---|---|

Hermle U630T | CNC machining center | |

Hermle C22 | CNC machining center | BFSA robot systems* |

Hermle C12 U | CNC machining center | BFSA robot systems* |

Hermle C12 U | CNC machining center | BFSA robot systems* |

Haas VF-2SS | CNC machining center | |

Haas 500 UMC | CNC machining center | BFSA robot systems* |

Haas 750 UMC | CNC machining center | |

Haas 750 UMC | CNC machining center |

TruPulse 156 | Laser seam and spot welding equipment |

Jäckle WIG201 | Welder |

LAMPERT Micro Arc Welder | Micro TIG welding machine |

Lasit Laser Compaktmark | UDI Marking laser |

Scriptograph Compaktmark | UDI Marking laser |

Opticline CS305 | Optical shaft measuring system |

Aberlink Axiom | 3D coordinate measuring machine |

Mitutoyo QS250Z Vision System | Optical coordinate measuring equipment |